Testing

Tried and tested, again and again

We’re constantly testing our technology to prove why Crimsafe protects your property best – not just against the threat of intruders, but against bushfire, cyclone, pests and more.

Crimsafe outperforms the rest

Australian Standards set out the level of quality required for all Crimsafe products sold. At Crimsafe, we don’t just meet those standards – we’ve developed our products to exceed them and we go above and beyond to set the highest standard for security screens.

Crimsafe passes or exceeds standards for impact, jemmy and knife-shear testing to ensure our screens provide the highest level of protection against intruders.

In addition, Crimsafe security screens are energy efficient, corrosion resistant, filter UV rays and provide fire attenuation protection.

Explore our results and see how our security doors and windows can protect your family, and how we compare to our competitors.

Superior strength against impact

The first impact delivered by an attacker is usually the most violent. Dynamic impact testing measures how well a security screen holds up to the full force of a criminal’s kicks, punches or charges. The force of impact is measured in ‘joules’.

When tested, Crimsafe screens stood up not just against an Australian Standard of 5 x 100 joule impact – but against singular impact levels reaching 550J (Crimsafe Regular), 750J (Crimsafe Ultimate) and 1200J (Crimsafe Heavy-Duty).

The security screen industry refers to ‘Australian Standards’ which include testing for the ability to withstand a certain level of impact.

This is relevant to the strength of the security screen and the impact it can withstand in the event of a break-in attempt.

While many security screens ‘meet’ the minimum level of impact required by Australian Standards, Crimsafe has been designed to exceed it.

Independent research conducted by the University of Queensland tested a wide range of security screens. Crimsafe exceeded the impact level required by Australian Standards and far out-performed competitor products, making Crimsafe the strongest stainless steel security screen system on the market.

What is the Australian Standard?

The Australian Standard (AS5041-2003), sets out requirements for a ‘Dynamic Impact Test’. This simulates the effect of a human impact against a security screen and is measured in ‘Joules’ (a unit of energy).

The Australian Standard requires a security screen to withstand five single impacts of 100 Joules each. This was established in the Australian Standards for glass (AS1288) and was adopted by the security industry.

The average Australian male, weighing 86kg, can easily exert more than 100 Joules of force in a single impact.

That’s why Crimsafe has been designed to exceed the minimum requirement of Australian Standards.

University of Queensland Test Results

The University of Queensland tested Crimsafe and competitor products for their ability to withstand single and multiple impacts.

The test screens are initially impacted to the level required by the Australian Standards (5 x 100J), after which they are subjected to increasing impact levels. The graph at right shows that many competitor products could not meet the recommended Australian Standard, failing to withstand five impacts of 100 Joules each.

Crimsafe withstood the multiple impacts required by the Australian Standard and withstood a single impact of 550 Joules (Crimsafe Regular), 750 Joules (Crimsafe Ultimate) and 1200 Joules (Crimsafe Heavy-Duty).

Resistant to knife attack

Home intruders will often attempt to slash security screens with a blade to gain access to your home. All Crimsafe screens easily pass the Australian Standard Knife Shear Test, because all Crimsafe screens come equipped with our unique Tensile-Tuff® mesh – the industry leading 0.9mm, 304 grade high tensile structural grade stainless steel security mesh.

The Knife Shear Test

This test is designed to simulate a knife attack on a screen, using the kind of small to medium blade favoured by home intruders.

A test screen is mounted horizontally in a rigid frame and a heavy duty trimming knife is pulled along the mesh with a force of up to 350N (35kg) and a constant downward pressure of 150N (15kg) for a distance of 250mm.

The test is performed three times along the same line with a new blade fitted each time. In order to achieve a pass the mesh must not be penetrated in a continuous line for more than 150mm.

The Results

With our industry leading 0.9mm, 304 grade high tensile stainless steel Tensile-Tuff® mesh, all Crimsafe screens pass this test.

The specifications pertaining to the mesh and other products that we supply are our target specifications. The actual specifications for items supplied may differ taking into account reasonable manufacturing tolerances.

No leverage for tooled attack

Lever tools (like screwdrivers) are popular among home invaders because some security screens have weak points in their construction – making it easy to lever apart the frame, lock or hinges.

But they’re no match for a Crimsafe screen. Years of development and rugged construction mean that all Crimsafe products meet Australian Standards in every section of the lever attack or jemmy test.

The Lever Attack Test

The Australian Standard requires a rotational force of up to 450N (45kg) to be applied and held for 20 seconds at all locking, hinging and fastening points around your security screen.

A large screwdriver is inserted at these points and mechanically rotated until either the force required or 80° rotation has been achieved. A security screen door must remain securely locked and a window security screen must remain securely fastened to the window that it is covering to achieve a pass.

The test panel fails if all the hinges, or all the locking points or all the fastening points (screws holding a window section onto the wall) fail, or if the edge of the security door or window has deflected to make a gap wider than 15cm.

The Result

Crimsafe passed easily and meets the Australian Standard requirements. Our ongoing research in this area has enabled us to develop Crimsafe Ultimate, our product range with true lever defiant design to give you the ultimate protection.

Too tough to pull down

If they can’t use brute force to smash through a screen, criminals will try to attack the edges of a security screen, and pull it from its housing.

The Australian Standard Pull Test investigates how well a security screen can withstand these kind of attacks.

Every Crimsafe screen meets the Australian Standard requirements. Our unique Screw-Clamp technology ensures that the mesh can’t be pulled from the frame at all, and the rigid Tensile-Tuff® mesh guarantees no hand hold.

The Pull Test

This Australian Standard Pull Test is designed to simulate an attack by an intruder in an attempt to pull at the security screen either at the bottom, middle, side or top of the screen. The test also assesses the integrity and fixing of the mesh into the screen frame.

The Results

Crimsafe passed and meets the Australian Standard Pull Test requirements.

Rated for balustrade and fencing

The superior protection offered by Crimsafe screens isn’t just limited to the inside your home – they can also be used for balustrades and fences.

Crimsafe panels have passed industry standard testing (AS/NZS 1170-2002), which allows them to be used as balustrade screen infills and as fencing, keeping your family protected from falling hazards while continuing the clean Crimsafe aesthetic across your property.

The Balustrade Test

The test requires an infill panel to be subjected to a load test, replicating outward and inward pressure onto a balustrade infill panel.

The Results

The Crimsafe panel not only met the test requirement of 1.4 tonnes, but exceeded it, withstanding a massive load of 4.2 tonnes. This impressive result was attributed to the unique design of Crimsafe Screw-Clamp technology. The Crimsafe infill panel also complies with occupancy type C5 (areas susceptible to overcrowding).

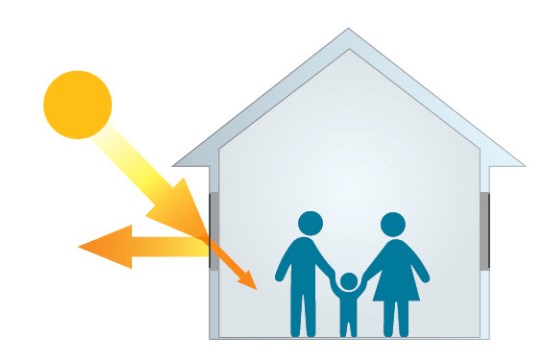

An energy efficient solution

The Australian Window Association (AWA) estimates 40% of a home’s heating energy is lost through windows and up to 87% of a home’s heat is gained through windows.

And with electricity prices rising, choosing energy efficient fittings has never been more important.

Crimsafe screens have undergone a range of energy efficiency testing and have been shown to improve the energy efficiency of a window by up to 53%.

When you choose Crimsafe, you’ll not only stay safe and look smart, but you’ll save money on your energy bills too.

The Solar Heat Gain Test

A major element of determining a window’s WERS (Windows Energy Rating Scheme) rating is its Solar Heat Gain Coefficient (SHGC). The SHGC is the measure of how well a window blocks heat caused by sunlight.

To test this, a Crimsafe security screen is applied over a glazed window to measure how well the screen blocks heat produced by sunlight entering into your home.

The Results

Crimsafe Security Screens were found to improve the energy efficiency of a Window by up to 53%.

When Crimsafe is applied over a 3mm generic single glazed window the cooling efficiency of the window increases from zero stars to a 3 Star cooling rating, keeping your home cooler in summer and reducing heat loss in winter.

The Window Energy Rating Scheme (WERS) recognises that Crimsafe improves the cooling and heat retention of a building when applied to glass windows and doors.

The effects are best seen when security screens are placed over your entire window, not just over the opening portion. The type of window glass and glazing will also impact cooling and heat retention.

When Crimsafe is applied over a generic single glazed window the cooling efficiency of the window increases from zero stars, no additional benefit to a 3 Star WERS rating with a reduction in solar heat gain of up to 53%, keeping the interior of the home cool in the summer.

In the winter months Crimsafe works with your windows to limit the escape of warmth from your home, and heat retention efficiency increases. The heating rating improves from zero stars no heat retention benefits, to a 1.5 Star WERS rating with Crimsafe applied.

When Crimsafe is applied over 6.38 Clear Low E glass, the cooling rating increases from a 1.5 Star rating to a 4 Star rating greatly enhancing the cooling attributes of your glazing investment.

Annual energy performance (stars and % improvements) are calculated using Nationwide House Energy Rating Software according to procedures of WERS 2008 and the results are presented in Standard International Units.

No corrosion under harsh conditions

Over time, some steel security screens can be overcome by the demands of coastal or harsh environments, sacrificing both their protective strength and the aesthetics of your property. Crimsafe screens have passed corrosion tests above and beyond normal industry standards.

Which is why we put Crimsafe screens through comprehensive corrosion testing – the Australian Standard Salt Spray Test (AS 2331.3.1), and even more rigorous Prohesion Accelerated Test (ATSM G85).

And where other screens fell down, we passed every test with flying colours, meaning your Crimsafe screens will look great and stay strong for longer.

A 1,000 hour salt spray test is a common measure for corrosion in stainless steel security products. This is equivalent to approximately 10 years environmental exposure. Crimsafe passed this test, but also passed a much tougher test – 3,000 hours in the Prohesion Accelerated cyclic test.

The Salt Spray Test

In the industry standard Salt Spray Test, a salt solution is sprayed at the test samples for 1,000 hours, simulating 10 years of exposure to very harsh weathering conditions. (AS 2331.3.1)

The Results

The Crimsafe security screens tested passed a massive 3,000 hours with no corrosion, our Tensile-Tuff® security mesh passed 10,000 hours with no corrosion.

The Prohesion Accelerated Test

Crimsafe security screens also pass the Prohesion Accelerated test (ATSM G85), which provides a better correlation with real-world outdoor exposure results.

Prohesion tests use a method of cyclic accelerated corrosion and are designed to evaluate how well the surface coatings of the Crimsafe screen protect from corrosion.

The Results

Crimsafe passed 3,000 hours with no corrosion.

Designed for all conditions

New Zealand experiences some tough environmental conditions, with high levels of UV radiation and extreme heat throughout the summer months.

Crimsafe screens have been designed to protect your family from both these factors, blocking 62% of harmful UV rays from entering your home while allowing superior airflow to keep your property cool.

The UV Light Test

The UV light test uses an instrument called a UV spectrophotometer that measures the intensity of light.

In this test the intensity of light from a UV lamp is measured before and after it is passed through a sample of Tensile-Tuff® mesh.

The Results

Crimsafe Tensile-Tuff® security mesh was found to filter 62% of UV radiation.

A major factor for the high UV resistance of Crimsafe security screens is the thickness of the wire used for the mesh: the thicker the wire, the less UV will penetrate through the aperture of the mesh.

The Airflow Test

Crimsafe Tensile-Tuff® security mesh was tested in a custom designed wind tunnel to determine the effect of the screen on air flow. The test measured the flow of the air exiting the screen.

The Results

Crimsafe screens allow on average 53% airflow. Compared to insect mesh, Crimsafe allows much better airflow through your home and helps maintain a healthier home interior in all seasons.

Storm and cyclone protection

Doors and windows are the hardest part of your home to protect against the violent, debris-carrying winds of cyclones or severe storms. Crimsafe helps protect your home against hail and wind-borne debris. Specialty cyclone-debris protection products are also available.

Able to stand up to projectiles and debris from wind gusts up to 392kph, the superior strength of our Tensile-Tuff® mesh combines with our unique Screw-Clamp technology to make sure your family will be protected and secure before, during and after the storm.

The Cyclone Debris Test

The Cyclone Debris Screens (AS1170.2:2011) is conducted in two parts. An air cannon fires a missile at predetermined air pressures to generate the required impact speeds for Australia’s Cyclone Regions C & D.

- The screen is impacted with a 4kg piece of timber fired from the air cannon

- The screen is impacted with an 8mm steel ball repeated five times in different areas of the screen

The Results

A wide range of Crimsafe products are approved for use in Cyclone regions C & D, including Crimsafe doors, windows and Crimsafe Safe-S-Capes®, which all meet the 36 m/s requirement.

Our specially designed Crimsafe Cyclone Debris Screens pass the highest levels for Cyclone Debris Screening required for regions C & D, withstanding impact up to 44 m/s.

Crimsafe Cyclone Debris screens can protect your home or business against storm driven debris from wind gusts up to 392kph, while providing security from intruders, superior airflow and outlook.

Our research and development program is continually advancing the limits of Crimsafe Cyclone Debris Screen performance.

Resistant to bushfire attack

In recent years, bushfires have caused huge losses of life and property.

In response, Crimsafe has tested its security screens to meet the highest levels in bushfire protection – BAL FZ.

Our screens provide excellent protection from ember attack, reduces radiant heat and will protect glass from the impact of burning debris.

The Ember Attack Test

The Australian Standard (AS3959-2009) requires screens which cover openings to be made of corrosion resistant steel, with an aperture size that will not allow a circular probe of 2mm diameter to pass through.

The Results

Crimsafe can protect your home across all Bushfire Attack Levels up to and including BAL-FZ.

Bushfire protection is required on sites where the Bushfire Attack Level (BAL) has been determined as one of the six levels of risk.

Prevents the spread of fire

Fire attenuation measures how well building materials reduce radiant heat and the spread of flame - and is a requirement of many building projects.

Crimsafe screens have been tested to meet Australian Standards for heat attenuation, and can be used as an alternative solution to the fire protection standard, with consultation from a qualified fire engineer or certifier.

This offers you flexibility in your building designs and savings on cost.

The Fire Attenuation Test

A Crimsafe screen is placed over an opening of a furnace constructed in accordance with AS 1530.4 and the reduction of radiant heat is measured.

The Results

Crimsafe has achieved up to 59% attenuation of radiant heat.

This means a Fire Certifier or Fire Engineer can put Crimsafe forward as an “alternative solution” for use as a Fire Attenuation screen. The Fire Certifier or Fire Engineer will base their decision on the information from the Test Report, their assessment of the building and the level of fire risk or potential risk surrounding the building.

Final approval of the installation of security screens for the purpose of fire attenuation will need to come from the Building Certifier or the Fire authority.

For architects and specifiers, the Test Report is available on request. Email projects@crimsafe.com.au to request a copy.

Insect resistant

Crimsafe has built our reputation on keeping intruders out – and this includes even the tiniest ones.

Crimsafe security mesh has been tested specifically for its effectiveness at stopping dengue fever mosquitos (gedes aegypti) – and was found to prevent 99% of mosquitos from entering over a 72-hour period. There’s no need to sacrifice airflow with standard mosquito screens – trust Crimsafe to keep intruders of all sizes at bay.

The Insect Resistance Test

Crimsafe’s Tensile-Tuff® security mesh has been tested for its ability to keep dengue fever mosquitos (aedes aegypti) away from a food source in a testing chamber. Hundreds of mosquitoes were trapped in between the mesh which was then left up to 72 hours before the testing was concluded.

The results

Crimsafe Tensile-Tuff® security mesh prevented 99% of the mosquitos from passing through the mesh over the test period. Which is especially important given recent research about the potential impact of climate change on increasing dengue mosquito distribution.